Rapid Online Laser Cutting Services

Pintejin Group provided our clients real custom Laser Cutting prototyes parts with quick turn delivery.Quotes in hours, we manufacturing quick custom prototype laser cutting parts

Our multiple laser cutter and bending machine are staffed by very experienced engineering specialists.Our HANS laser cutting machines can handle small radius cuts and maintain a high quality level whether you want one piece or one hundred, we offer you a variety of laser cutting services including pipe laser cutting parts, plate laser cutting parts, large parts cutting and wire EDM, surface grinding and much more.Our Normal delivery date is 8 to 15 days.

Laser Cutting for Prototype Parts

Pintejin Group based in China, is an industry leader in rapid laser cutting online , the customers can get laser cutting prototyping in as fast as 5 day.

- If you are looking for a online laser cutting services in China for whatever stainless steel,aluminum or other metal laser cutting parts, Pintejin Group could be your best solution.

- We understand maybe you need just a single component or a number of laser cutting parts, we can help

- Our prototype machining services offers outstanding quality aluminium, copper, brass, stainless steel parts or ABS, POM, plastics etc.,

- We don’t have a Online instant Quote system, however quotes are available within hours, parts ship in as fast as 3 day

- We have the capacity to scale all your products projects from prototyping to production quantities effortlessly

Custom Laser Cutting Services – Top China Laser Cutting Parts Manufacturer & Factory

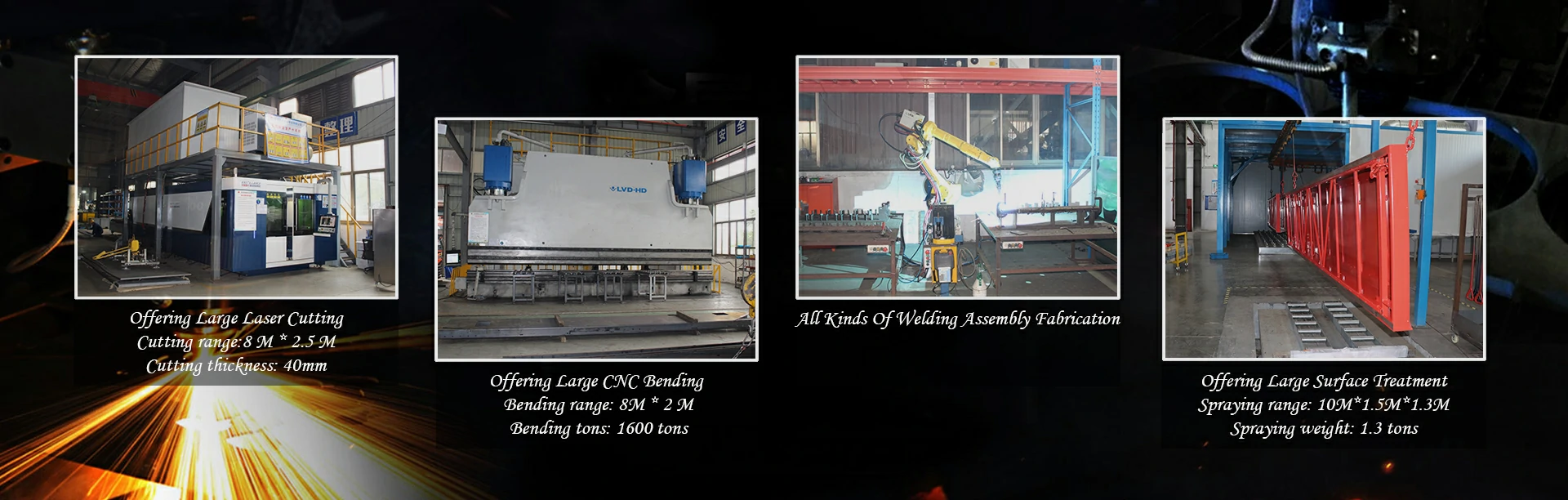

Pintejin Group provides a variety of laser cutting services including fiber laser cutting, sheet metal, industry welding, cnc machining , bending and surface grinding. With 12000W 8m*2.5m Han’s Laser Cutting Machine, 8000W 6m Han’s Laser Cutter, 6000W 6m Han’s Laser Cutting Machine, 4000W 8m Han’s Laser Cutter, combined with other advanced capabilities and our experienced team, we can handle all types of laser cutting parts in both metal and non-metal materials. Whatever you need prototypes or production parts, our laser cutting services will be your best choice. Contact us today to get your machining parts done in as fast as 5 days!

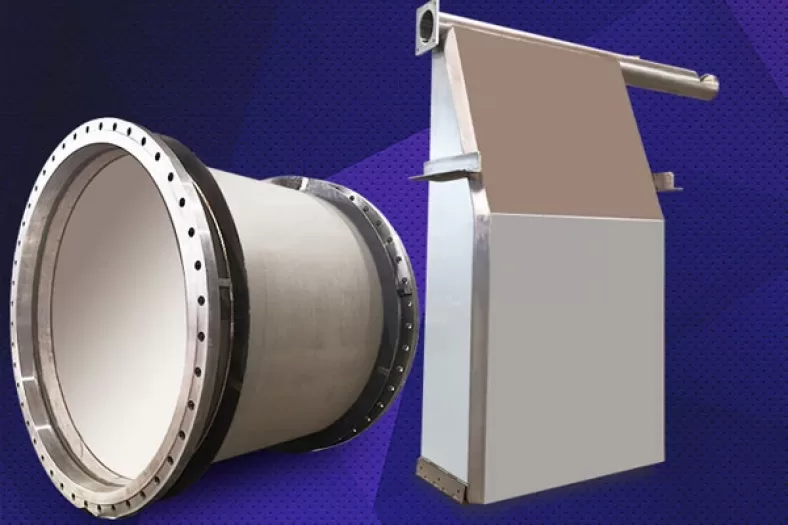

Tube Laser Cutting

Tube Laser cutting is used to aid the use of tubes in the agricultural, construction, aerospace, automotive, electrical and medical industries for applications that range from prototypes to large production runs or basic engines and flow systems.

Whether you need 80,000 cut tubes in 24 hours or a brand new highly engineered solution for a micro or a large part … Pintejin Group is your competitive source.We provide comprehensive services for tube cutting, tube bending, tube forming, engineered tubes, tailored blanks, tube machining, and custom tube fabrication and pre-assembly.

ISO 9001:2015 certified CNC laser cutting & tube laser cutting services to eliminate burrs & secondary operations in fabricated tubing assemblies.Capable of handling up to 50 ft. length, 20 gauge to 5/8 in. wall size, and 1/2 to 14 in. outside diameter. in less material scrap, quantities from one piece to thousands.… providing you with simpler, lower-cost solutions. Through years of experience, continuous education, the latest equipment and a small, highly-trained staff, Pintejin Group is your edge for tubular solutions.

Explore Our PIPE/Tube Laser Cutting Capabilities

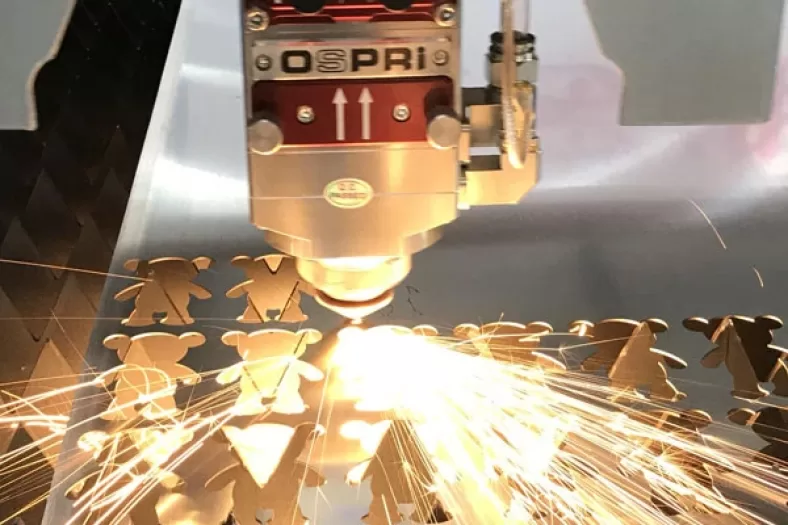

Plate Laser Cutting

Plate laser cutting is the process of use precision by laser, in order to cut through metal or non-metal sheet. Our commonly used laser cutting methods are; fiber laser cutting and cnc laser cutting….

Pintejin Group is your competitive source.We provide comprehensive services for plate cutting,plate bending,plate forming, engineered sheet, tailored blanks, plate machining, and custom sheet fabrication and pre-assembly.

ISO 9001:2015 certified. custom manufacturer specializing in the production of high volume sheet parts and metal fabrication, including laser cutting and robotic welding. Facilities contains over 20 presses in the laser cutting department and 8 high speed laser cutters in the metal fabrication department.Cutting can be done on parts in thicknesses up to 0.125 in., lengths up to 200 in. and widths up to 40 in. with +/-0.002 in. tolerances. Capabilities include etching and prototyping, Pintejin Group is your edge for plate cut solutions.

Explore Our Plate/Sheet Laser Cutting Capabilities

Why You Can Trust Pintejin To Deliver

Turning your vision into a reality is no simple feat. You need to entrust your ideas to a laser cutting expert that will handle the manufacturing process swiftly and with the utmost professionalism.

We strictly implement ISO quality standards and have received ISO 90001: 2015 and ITAF 16949 certification. This means our production lines feature advanced laser cutting technologies that give manufacturing precision and accuracy. With sophisticated measuring and testing equipment in house, we check all incoming material and parts to meet your specifications. That’s why we are outstanding among the laser cutting companies in China. Learn more about our quality control system and Equipment List. What’s more:

- Instant Quoting: Generally, quotations will be delivered in hours after submitting RFQs with clear information.

- 30 Years in the Fabrication Industry : Having carried out rapid prototyping and rapid manufacturing for 30 years, our engineers have built up rich experience. We can handle all types of projects.

- Massive Network Capacity : Our in-house facilities allow us to get your projects done fast. And thanks to our strong relationship with rapid manufacturing partners, our capacity is not limited.

- 30000+ Projects Delivered : Over 30K projects have been sent to our customers worldwide in the past 30 years, and we have received countless positive comments.

- Fast Turnaround : Unlimited capacity, experienced engineers and a flexible production system allow us to create your prototype and production parts in a short period.

- 2000+ Happy Customers : Our goal is to keep every customer happy with reliable quality, fast turnaround and great services. We want all our new customers to become long-term customers.

The Case Studies Of Laser Cutting Parts

Need online laser cutting suppliers for mass production parts? Pintejin is known as the best laser cutting manufacturer in China. With mold making facilities in house and resources from our partners, we are able to provide rapid laser cutting service for all type of metal material or non-metal material. We offer low-cost local production laser cutting parts and high-quality sheet metal parts for all your project needs.

-

8mmX6m Laser Cutting Of Logistics Telescopic Machine Shell

-

Industrial Welding Railway Rack And Chassis

-

Rounding Machining Custom Large Turner Guardrail Parts

-

8mmX7.5m Large Industrial Exhaust Fan Pipeline Welding

-

16mmX5m Non-Ferrous Metal CNC Bending Parts

-

Stainless Steel Crafts Laser Cutting

-

Fiber Laser Cutting Stainless Steel 316 Bar

-

16mmX5m Steel Laser Cutting Parts

-

12mm Steel Laser Cutting Parts

-

Irregular Stainless Steel Silo By Sheet Metal

Laser Cutting Parts Or Sheet Metal Parts Delivered Fast with 8 Simple Steps

We based in China are well equipped to handle the demands for Custom metal laser cutting services owing to our state of the art infrastructure and many years of experience in this field. The field of laser cutting services is however full of diverse services that are unique to unique needs.

Upload a CAD File

To start, simply fill in a few information and upload a 3D CAD file.

Quote & Design Analysis

You’ll receive a quote shortly, and we’ll send you design for manufacturability (DFM) analysis if necessary

Order Confirmation

Once you review the quote and place your order, we’ll start the manufacturing process. We also offer finishing options.

Removal Of Material

Laser Cutting Or Sheet Metal desired shape is obtained by the process of cutting which removes the unwanted metal from the original sheet.

Deforming The Material

This stage involves the deformation of the material into the desired 3D shape with the help of different tools and machining practices for bending and forming of metal sheets.

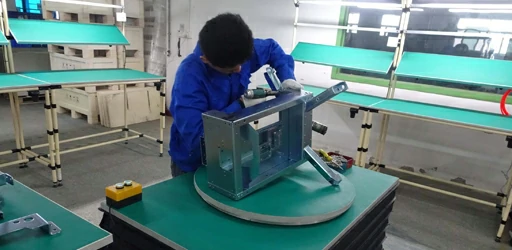

ASSEMBLY

This stage involves the assembly of all the component parts of the machine part, which might be formed by the assemblage of many different processed pieces.

FINISHING

The Last manufacturing and an extra stage to the entire process is the process of finishing, which needs to be done before selling the custom machine part commercially so as to make the final product look absolutely perfect.

Parts are Shipped!

Your Laser Cutting Or Sheet Metal prototypes or custom manufactured parts will be inspected and delivered straight to your doorstep

More Service In Pintejin Group

We based in China are well equipped to handle the demands for Custom metal laser cutting services owing to our state of the art infrastructure and many years of experience in this field. The field of laser cutting services is however full of diverse services that are unique to unique needs.

-

Fiber Laser Cutting

Fiber laser cutting services for steel, stainless steel, aluminum, copper, brass and various other materials. Capable of cutting materials up to 0.70 in. and cutting accuracy up to +/-0.010 in. Worktable size ranges from 120 in. x 60 in.

-

Sheet Metal

Precision sheet metal fabrication services for steel, stainless steel, steel plate, carbon steel, aluminum, brass and copper. Capable of fabricating parts up to 0.250 in. ga. material thickness, 60 in. sheet metal width and +/-0.010 in. tolerance.

-

Welding

Welding for aerospace, automotive, electronics, military, medical and other industrial applications. Types include continuous strip, electron and laser beam welding. Capable of handling parts up to 90 in. OD x 192 in. length.

-

Metal Finishing

First-class electrostatic spraying, sprayed surface treatment equipment, professional surface treatment capabilities such as pickling, phosphating, neutralization cleaning, etc., provide the most reliable surface adhesion for parts

-

Cnc Bending

In-house bend die tooling, standard bend radii from tight mandrel bends to large sweeping roll bends, close tolerances, long & short runs, bending of uncoated & coated materials. 3/8 in. – 10 in. diameter tube capacity.