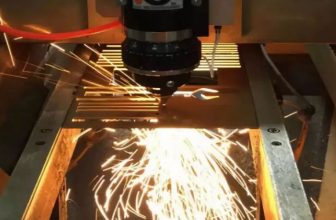

With the rapid development trend of the industrial production laser industry chain, the sales market hasLaser processing welding.The technical requirements are getting higher and higher, and the laser equipment has gradually changed from a single application to a diversified application.Laser processing weldingThe level is no longer a single laser cutting or electric welding. The sales market has more and more requirements for the integration of laser cutting and electric welding for laser cutting processing. Fiber laser cutting and metal laser welding machines are integrated with laser cutting and welding. Machinery and equipment should be born from time to time.

Laser welding is a high-efficiency and high-precision way to carry out electric welding by using the focused particle beam as the calorific value caused by the negative electron welding parts of the power source. .Laser processing weldingIt is one of the key aspects of the key technology of laser raw material production and processing. In the 1970s, it was mainly used for electric welding of thick-walled raw materials and low-speed electric welding. The whole process of electric welding is of the thermal conductivity type, that is, the laser radiation source heats the surface of the steel part, and the surface heat diffuses to the inside and outside according to the heat conduction. The main parameters such as the total width, kinetic energy, high-value output power and repetition frequency of the single pulse of the laser make the steel melt and produce a special molten pool.

BecauseLaser processing weldingIt has been successfully used in high-precision electric welding of micro, small and medium-sized parts.Laser processing weldingIt is to use a single pulse of high-efficiency energy laser to heat the raw material in a small area. The kinetic energy of the laser radiation source diffuses to the inside and outside of the raw material according to the heat conduction, and the raw material is melted to produce a special molten pool. It is a new welding method,Laser processing weldingThe key is for electric welding of thick-walled raw materials and high-precision parts, the speed is faster, the welding is flat, beautiful, and there is no need to solve or simply solve after welding, high welding quality, no air holes, precise manipulation, and small focus spot. , High precision level, easy to maintain automation technology.