Laser welding processing with other Laser welding processingIn contrast, it has the advantages of high-efficiency environmental protection and processing precision colleges.accompanied by Laser welding processingdevelopment trend, and its market prospect is very broad.Let’s talk firstLaser welding processingThe advantages:

- Electric welding that can maintain a variety of motion trajectories. The laser has strong specificity, which is also a very good practical effect for electric welding of irregular raw materials;

- Electric welding is sturdy. After the laser is focused, the light spot is small and the specific energy is high, which ensures that the light generates a pyrogenic zone in a very short period of time, and produces solid welding and spot welding after melting, cooling and crystallization;

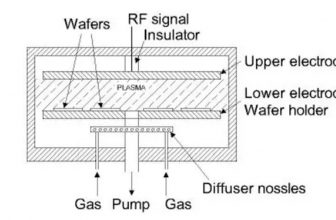

As everyone knows, everything has advantages and disadvantages.With the continuous development trend of laser equipment, for high precisionLaser welding processingThe existing problems are that the characteristics of the butt weld are weak, and the cost of consumables required by the machinery and equipment is high, which prompts everyone to choose a new plan to improve the heating of the steel by the laser, and use the laser hybrid electric welding.(Such as laser and low temperature plasma argon arc welding, dual particle beam welding)way, improvedLaser welding processingThe characteristics of the connector reduce the cost of machinery and equipment.

In summary,Laser welding processingIt is suitable for stainless steel plates and many delicate objects. Maybe it is afraid that the welding of small objects will become rough. Under normal circumstances, laser welding can be used.