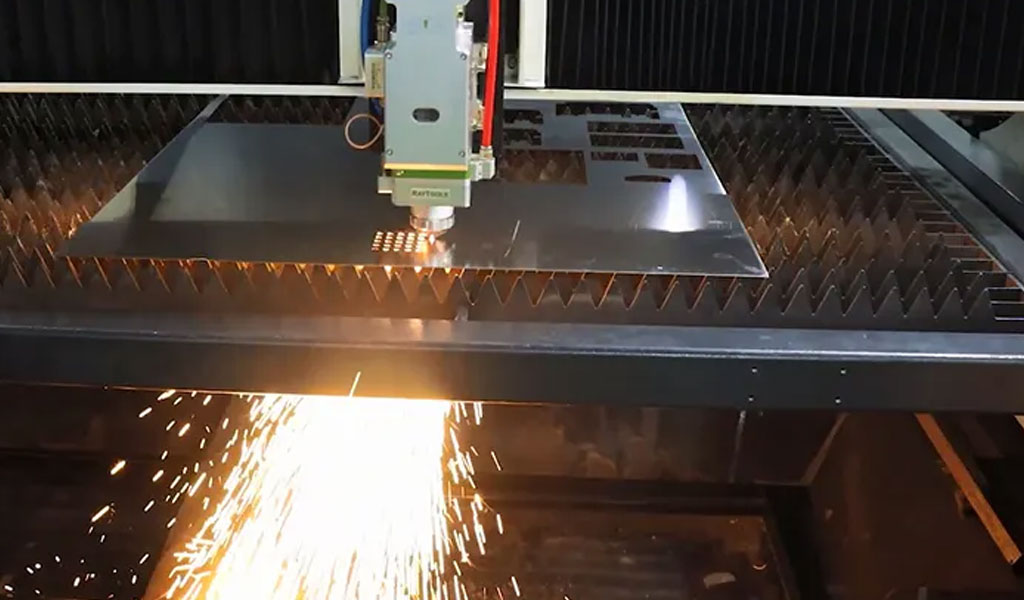

I believe we all know that heat deformation treatment is a very important part of the sheet metal shell processing process, in which we need to maintain a good heat treatment to prevent the deformation of the sheet metal shell products, therefore, we need to pay extra attention to the sheet metal shell processing heat deformation treatment method. So, do you know how the heat deformation treatment for sheet metal shell processing works? Sheet metal shell processing heat deformation treatment methods.

- 1、In the insulation process, the residual stress of the sheet metal shell processing will be released from the deformation, and the self-weight of the parts will also lead to deformation. In the cooling process, due to the different cooling speed of different parts of the part, thermal stress will be formed and the part will be deformed. Even if the cooling speed is the same, surface cooling is always fast and internal cooling is always slow.

- 2. The sheet metal shell becomes shorter during low temperature tempering, the amount of shortening is proportional to the supersaturated carbon content. When heated at room temperature – 200°C, it expands. However, due to the differentiation of the metal at around 200°C, the expansion does not change much. In the conventional heat treatment of sheet metal shell processing, the main cause of part shape change is the thermal and phase change stresses during the heating and quenching heat treatment. If the heating speed is too fast, the part is too large relative to the heating furnace, the temperature of each part is not the same, and the sheet metal will be thermally deformed.

- 3. In the heat treatment process of sheet metal shell processing, it should be noted that the parts should be placed vertically and put at the bottom when they are placed. In the process of cooling, the viscosity, temperature and pressure of the cooling substance can be changed, and some additives can be used when appropriate.

In summary, this is how to deal with thermal deformation in sheet metal shell processing. In order to effectively prevent the adverse effects of thermal deformation on us, in the process of heat treatment of sheet metal shell processing, attention should be paid to the vertical placement of parts, placed at the bottom, so that the impact on thermal deformation can be reduced to a very low level.