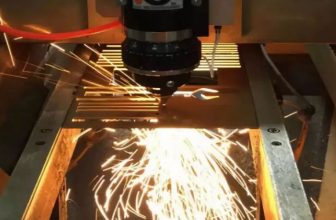

Laser welding processingIn order to ensure the safety and safety protection at any time, it is necessary to strictly control the laser damage, do a good job in project operation, safety protection and safety work, and how to operate it.

1.Engineering project manipulation

Engineering project manipulation refers to the manipulation of laser generators orLaser welding processingThe safety precautions adopted by the system software structure type, the key includes: protective cover——It is used to prevent workers from receiving more than the maximum allowable direct radiation; safety interlocking —— refers to the protective device connected to the protective cover, which can prevent the radiation source when the protective cover is removed; safety laser light path — right The irradiance will cause the laser light path of the ignition or secondary coil radiation source to be closed; key power switch – specifically when the key is removed, the laser generator turns; light stops – so that the particle beam does not cross the control plan. Production processing areas, where light stops or attenuators can be applied.

2.The Security Of Laser welding processing

The key refers to wearing fire-resistant, high-temperature-resistant laser protective clothing, laser goggles that can selectively attenuate wavelengths of special light, laser protective masks for ultraviolet laser sources, and wear that can prevent the effects of irradiation or transmission of lasers Laser Cut Resistant Gloves.

3.The Safe Job Of Laser welding processing

The key to safety work includes setting up competent authorities or staff, clarifying job responsibilities and control rights: including safety education and training and medical supervision.