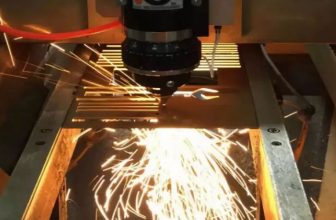

The sales market is booming, especially in recent years, many manufacturers have sprung up here like mushrooms after a rain, and sheet metal processing and manufacturing have already entered an increasingly fierce wave.But we have to deal with a reality, the sheet metal processing and sales market is in chaos, and the competition in the cheap market has caused The quality of production and processing varies. Let’s talk about which processing manufacturers are considered high-quality.Sheet metal bendingManufacturer.

1.The product must have quality assurance

Nowadays, many small processing factories produce cheap products that fill the sales market. Although customers will blindly follow the trend to select products based on cheap prices in the early stage, after several problems with products, customers have become more and more objective, and they will choose well-known products. Brand-guaranteed, quality-assured large-scale factories produce and process goods.Therefore a high-qualitySheet metal bendingThe products produced and processed by the manufacturer must be guaranteed in quality and quantity.

2. We has a sound pre-sale service and after-sale maintenance service

Sheet metal bendingIt is not a one-time daily necessities, and customers usually choose a large number of related products according to the application status after several purchases. At this moment, the service quality of pre-sale service and after-sale service plays a particularly important role. A high-quality sheet metal processing company can definitely provide customers with a good pre-sale service and after-sale service experience, and can ensure that it can be dealt with quickly if it is not very good. , allowing users to experience the ultimate shopping experience.

3.The scale of the manufacturer’s business

The processing plant operates on a large scale, with sound processing technology and excellentSheet metal bendingThe construction of a talent team for production machinery and technology. At this stage, the market competition of sheet metal processing plants is fierce. Many processing plants are all small processing plants. Their equipment is all old equipment replaced by large factories, and the processing plants are not fully equipped with machinery and equipment. Out of date, there is a shortage of technical professionals in technical fields.