Iron and steel metallurgy industry is the country’s basic industry, but also the country’s heavy industry. And its equipment is complex, many types, and heavy tonnage. Due to the existence of friction, wear and other reasons, in order to maintain the normal operation of the equipment, a large number of spare parts are consumed every year. Therefore, reducing the consumption of spare parts, the remanufacturing and maintenance of the used equipment has a positive role in reducing production costs and improving the economic benefits of enterprises, and there is a lot of room for cost reduction. Among them, laser remanufacturing technology has very practical significance for the maintenance and repair of spare parts, and for energy saving and consumption reduction of enterprises.

The Main Types Of Laser Remanufacturing Technology

1.Laser Hardening

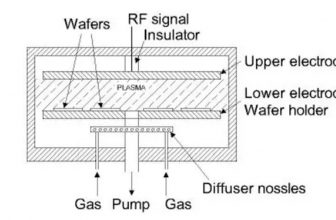

Laser quenching technology uses a focused laser beam to enter the surface of the steel, so that the temperature rises rapidly above the phase transition point. When the laser is removed, the heated surface is rapidly cooled to martensite due to the rapid thermal conductivity of the internal material that is still at a low temperature. Below the transformation point, the surface transformation hardening of the workpiece is achieved. For example, the maximum quenching depth of laser melt quenching on the surface of large rolls can reach more than 2mm.

2.Laser Cladding And Alloying

Laser cladding technology is a process that uses a laser beam to clad a layer of materials with special properties on the surface of a selected workpiece to improve the surface properties of the workpiece. For a large number of wearing parts in the metallurgical industry, such as rolls, guides, conveying rolls, nip rolls, scissors, etc., the biggest advantage of laser cladding and alloying technology is to convert the overall alloying of the rolls into surface alloying or cladding, It greatly improves the service life of wearing parts such as rolls. Clearly, the design, selection and proper use of alloy powders are the keys to the success of this technology.

3.Laser Welding

Laser welding is one of the important aspects of the application of laser material processing technology. The principle is to radiate high-intensity laser light to the metal surface through the interaction between the laser and the metal, melt the metal, and form a weld. Due to its unique advantages, it has been successfully applied to precision welding of tiny parts. For example, the typical cold rolling process route of my country’s iron and steel industry is: converter smelting – out-of-furnace refining – blooming – hot rolling – pickling – cold rolling – annealing – flattening – galvanized (tin) – finished product. In this typical cold rolling process, belt welding equipment is crucial. During operation, advanced steel strips and rear steel strips must be welded to ensure continuous operation of the production line. When the silicon steel plate is running online, it needs to be bent and deformed many times, bear a certain running tension, and has high requirements on the performance and quality of the weld.

Application Of Laser Remanufacturing Technology In Iron And Steel Metallurgy Industry

1.Repair And Strengthening Of Rolls

Most of the production equipment in the metallurgical industry work in harsh environments such as high (alternating) stress and high thermal stress, such as continuous casting rolls, straightening rolls, grooved rolls, semi-steel rolls, casting tube molds, hot (cold) rolling work rolls, Blast furnace chute, material clock, etc. Among these equipments, various rollers are undoubtedly one of the most critical equipment components, which consume a lot of money and are expensive. The service life is not only closely related to the product cost, but also directly determines the quality of steel products, especially the surface quality and plate type. . Various rolls are repaired by laser surfacing, among which small rolls and local repair are better. If the performance can be new.

Laser quenching technology can strengthen the surface of various guide rails, large gears, journals, cylinder inner walls, molds, shock absorbers, friction wheels, rollers, and roller parts.

2.All Kinds Of Shaft Parts Wear, Hold Tile, Crack Repair

After laser surfacing treatment, the surfacing layer of various shaft parts has no rough casting structure, the surfacing layer and interface structure are fine, the grains are refined, and there are no defects such as holes, blisters, inclusions, and cracks, and the performance is like new parts.

3.Repair And Strengthening Of Various High Value-Added Gear Parts In The Metallurgical Industry

Laser surfacing technology can restore the performance of various high value-added large, medium and small gear components. Acceptance indicators are still in accordance with the original manufacturing standards.

4.Repair High-Pressure High-Speed Fan Blades

Due to the harsh working environment of the blade, the air inlet of the impeller blade is prone to serious corrosion and wear, and it is generally used for 3000~4000h, that is, the impeller blade is scrapped due to the balance of corrosion and wear loss. The repaired layer can be metallurgically combined with the original base material by using laser surfacing technology, and the hardness is about HRC55 or so. Service performance is like new.

Cost Analysis Of Laser Remanufacturing Technology

The biggest cost of laser processing is that the one-time investment in equipment is relatively expensive. Once the equipment is put into use, the operating costs are relatively low regardless of the equipment input cost. Since the rolls, shaft parts, blades and gears in the steel metallurgy equipment are all high value-added parts, the cost of laser processing is less than 25% of the original value. Moreover, the laser processing cycle is short, which can greatly save maintenance time, ensure timely production, and perform like new parts.