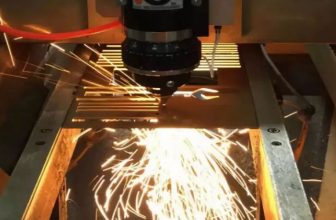

If there is an abnormality during the operation period, please stop the inspection immediately and operate again until the common fault is cleared.RollingThe latter steel parts should not be placed on the road immediately, but should be placed on the wooden floor of the fire truck. They should be stacked neatly and not so high as to block the corridor.

Clean up the rolling machine, abrasive oil, dirt, maintain machinery and equipment, and clean up after get off workRollingIn the surrounding environment of the machine and equipment, the CNC lathe should have a good grounding device. When inserting and pulling out the software, the cable or cable cannot be pulled out to avoid the solder wire being pulled out. Photoelectric switches, servo motors, etc. will not be affected by hard blocks, and The display also doesn’t work with sharp blocks. The power box should be placed in a naturally ventilated area, and can no longer work in dusty corrosive vapors.CNC lathes should be kept clean. It should be noted that the clamping block, guide rail slider and other guide grooves should not be dirty.

Add lubricating fluid to the drive chain and other drag components on time. During the cleaning and maintenance period, please cut off the switch power supply, check whether the oil volume of the e-mail box meets the oil reference line, supply oil for the lubricating point, clarify the motor switch, whether the vision of the gasoline pump is different, and Whether the hydraulic transmission system has been activated after it is started.When oil seeps, please use an electromagnetic induction pressure reducing valve to adjust the working pressure to ensureRollingThe working pressure of the system software can achieve the specified pressure.