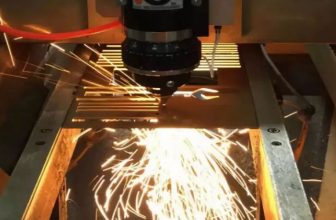

For many fiber laser cutting production and processing industries,Laser processing cutting;The use of machinery and equipment is very important, because the use of such machinery and equipment can make the production and processing of panels more effective, and can also provide a lot for the development of production and manufacturing. Convenience standard.In recent years, according to fiber laser cutting production and processing methods The manufacturing industry that performs the practical operation of laser processing of sheet metal continues to improve.liters, so everyoneLaser processing cuttingThe use of machinery and equipment is becoming more and more important.

In addition, choosingLaser processing cuttingcost can be controlled in the case of this type of processing technology able to confirm.To ensure the processing accuracy of raw materials, compared with other laser cutting methods, according toLaser processing cuttingThe method can be more accurate when laser cutting the board..It is in line with the processing technology specifications, and the general machinery and equipment cannot achieve such processing technology goals.Therefore, the application of fiber laser cutting equipment can save a lot of cost and capital investment for manufacturers.Laser processing cuttingThe use of machinery and equipment has also just begun to be paid more and more attention.

According toLaser processing cuttingThe manufacturer can also prevent the production and processing marks from being left on the board. When the machine and equipment carry out the laser cutting solution for the board, the laser cutting step is mainly carried out according to the laser. This kind of processing method Not only the speed is faster, but also the appearance quality of the board will not be affected.