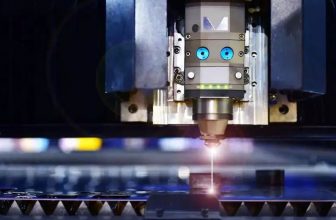

As an emerging industry, the development prospects are broad, and the automatic edge patrol of the laser cutting machine solves some defects in the cutting process very well. When cutting large-format and medium-thick metal plates in the sheet metal industry, in order to improve the utilization rate of the plate and facilitate programming, the straight edge of the plate must be parallel to the X-axis machining direction of the machine tool before laser cutting.

Usually, manual calibration is used, which has low efficiency, large error, serious material waste, and affects processing efficiency. We have applied the automatic edge finding function in the laser cutting machine, which is easy to operate, has high precision, and takes less time, which solves this problem well. Introduction of automatic edge finding function The large-format and medium-thick metal plates are placed on the closed machine table.

As long as the worker presses the “edge-finding” button, the equipment will calculate the inclination angle of the plate within a few seconds, and the coordinate system of the machine tool will be adjusted accordingly. Make sure that the X direction of the cutting is parallel to the direction of the long straight side of the plate.

System composition The hardware connection and composition required to realize the automatic edge finding function are shown in Figure

- Which mainly include CNC, servo control, linear drive, sensor, etc.

- The principle of automatic edge finding function When the sheet is placed on the table, if it is skewed, it may cause waste when cutting.

If the inclination angle and origin of the sheet can be sensed, the cutting process can be adjusted to suit the angle and position of the sheet, thereby avoiding waste. The automatic edge finding function came into being.

The automatic edge-finding function is applied to the laser cutting machine, which solves the problem of low material utilization rate during the processing of large-format and medium-thick metal sheets, saves the time for calibrating the sheet, effectively improves the production efficiency, and brings great benefits to users. The objective benefits are improved, and the automation degree of the processing and cutting machine is also improved.

ISO 9001:2015 certified custom manufacturer Custom Laser Cutting Services include custom precision machining, welding, fiber laser cutting and assembly services. Utilizing a 6-axis laser machine for cutting 2-D/3-D cutting, engraving, marking and sheet metal fabricating operations on metal sheets or tubular structures.