When making foam sculptures, the foam needs to be shaped and cut. Which equipment should be used to cut and shape the foam?

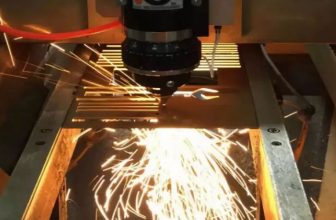

The Co2 laser cutting and engraving machine is ideal for cutting Pink Insulation Foam materials. Using a non-contact method, the foam will not be deformed or damaged. The heat of the CO2 laser will cut the sealing edge, the edge is clean and smooth when engraving, you do not need to rework. For excellent results in cutting foam, laser cutting machines are widely used to cut foam in some artistic applications.

- When cutting the ordinary plane, it is necessary to use the laser to cut the hollow. At this time, the large-scale lost foam needs to be cut with a three-dimensional CNC engraving machine.

- The laser cutting machine can generally cut 60W and 80W when cutting plastics. How much W needs to be used for the equipment depends on the thickness of the foam and the required cutting efficiency.

- Large-size laser cutting machine can be used in EVA, pearl cotton, foam, sponge products and other industries. The higher the power, the thicker the foam will be, and the faster the cutting speed will be.

- The choice of laser cutting machine depends on the relevant specifications such as the laser power and the size of the work surface.

- The feature of the laser cutting machine is that it can cut foam cotton, its cutting speed is fast, the precision is high, and the edges are not burned.

- The laser cutting and engraving machine is very suitable for cutting foam materials. It uses a non-contact method for cutting and engraving, which will not deform or damage the foam. The heat of the laser will cut the sealing edge, the edge is clean and smooth, and no reprocessing is required. made.

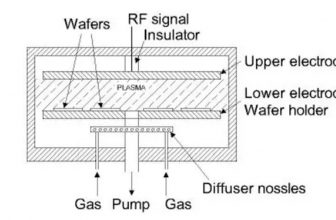

CNC engraving machine includes laser engraving machine, woodworking engraving machine, advertising engraving machine, stone engraving machine, glass engraving machine, laser cutting machine, plasma engraving machine, whether it is laser or CNC, it belongs to the same kind.

What’s Special About Laser-Cut Foam?

The laser is a highly flexible tool: anything from rapid prototyping to mass production is possible. You can start right from the design program, which is especially critical for rapid prototyping. Compared to complex water jet cutting processes, laser equipment is significantly faster, more flexible and more efficient. Foam cutting with a laser creates clean fused, sealed edges.

Does The Material Have To Be Fastened To The Work Surface?

no. The laser does not put any pressure on the foam during laser cutting, so no clamping or any other type of fixation is required. Just load the workpiece, start the laser processing and that’s it. This will save time and expense in material preparation.