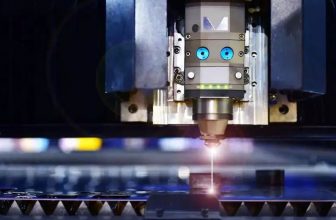

Laser fabrication is one of the non-contact advanced fabrication technologies based on thermal energy. It has the advantages of fast fabrication speed, small material deformation, low fabrication noise, small cutting seam, high efficiency and high precision, which is conducive to the realization of digital processing. Therefore, it has been called “the universal machining tool of the 21st century” in various engineering material fabrication fields.

At present, laser fabrication has been widely studied and applied in the fields of metal, ceramic machining, plastic products and wood processing. Domestic wood resources are relatively scarce, especially precious wood resources. Facing the growing demand for wood, how to improve the comprehensive utilization rate of wood and increase the added value of products has become an important issue in wood processing and manufacturing.

The use of advanced laser fabrication and manufacturing technology can increase the output of processed products, and improve the surface adhesion and finishing performance after processing, which is of great significance to alleviate the contradiction between the supply and demand of wood resources and the growth of demand, and improve the quality of processed products.

So What Are The Main Applications Of Laser Technology In Wood Fabrication?

a.Wood Laser Cutting

Laser cutting is widely used in laser fabrication technology. It has fast speed, high refinement and adaptability, fine kerf, small heat-affected zone, and automatic control during the cutting process. The laser cutting technology adopts non-contact processing, which can minimize the fabrication deformation, will not cause cracks in the wood board, and reduce material waste; and the laser fabrication speed is fast, the precision is high, and the incision is smooth, and generally does not require subsequent processing. These are incomparable with traditional cutting methods. Relatively speaking, the cost performance of wood board laser cutting machine is still very high.

b.Wood Laser Engraving

Laser engraving of wood materials is a very potential surface decoration technology of wood, an important technical means to provide value-added wood surface. Wood laser engraving mainly irradiates the surface of wood products with high-power laser, converts light energy into heat energy, and generates cracking and carbonization through instantaneous heat flow. In this way, the surface of local wood materials is eliminated, and the patterns and characters of the pattern engraving provided by the software are formed.

c.Laser Heat Treatment

Laser heat treatment of wood surface is one of the methods of wood modification. At present, on the market, mainly by laser heat radiation effect, the surface of wood is treated to change the physical and chemical changes of its internal properties and appearance. At present, laser heat treatment can be mainly used for the improvement of wood surface color and surface wettability, the performance of surface coating materials and the increase of anti-corrosion and mildew resistance.

d, Laser Marking

Early laser fabrication has been widely used in cutting and welding processes. Due to the pulse width from nanosecond to femtosecond laser sources, in recent years, it has been applied to other mechanical processing such as marking, marking, selective ablation and surface engraving of materials such as metals, ceramics, polymers and wood, etc. The principle of laser marking and laser engraving is the same, which is the use of high-power laser radiation to affect the surface of wood with marking images, text, etc.

The Plank Cutting Tips Of Wood

- The higher the power, the deeper the cutting

- The faster the speed, the shallower the cut

- In order to protect the lens and get the best effect when cutting, try to blow as hard as possible

- The best focal length can obtain the best cutting effect. When there is no special application, the laser cutting machine uses a focal length of 6mm

It can be seen that the content of the past few issues is related to the setting of parameters, so today, I will share with you a special content-materials. We all know that laser cutting machines have different parameters for different materials. So, follow the steps of the little experts and enter the content of specific material cutting skills.

Tool Material:

- A Feiyue laser cutting machine

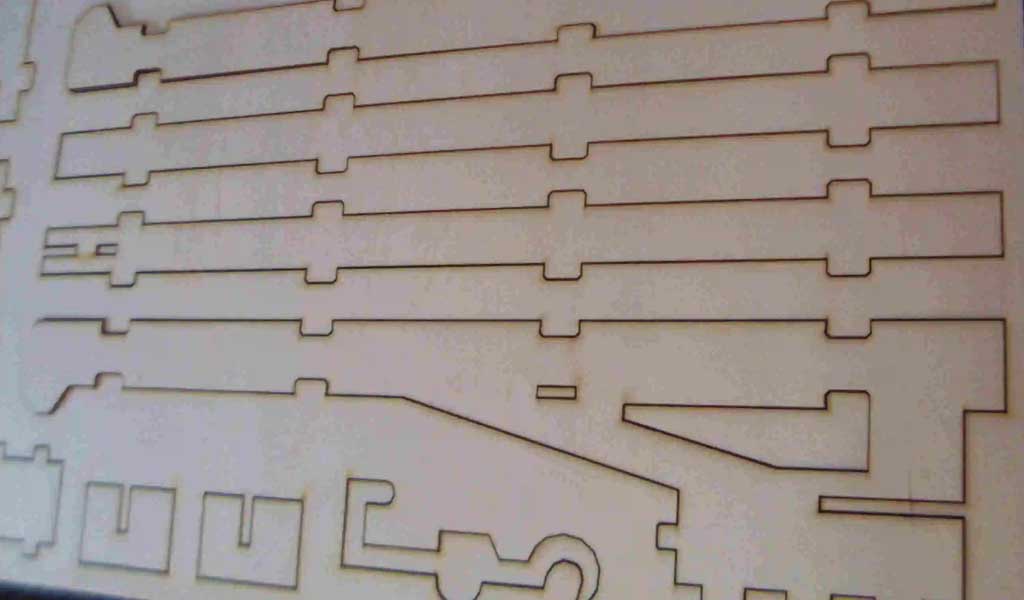

- Several 3mm thick plywood boards

Parameter Settings:

- Cutting speed: 35mm/s

- Cutting power: 45% – 50%

- Cutting focal length: 6mm

- Whether to blow: strong blow

We also know that wood boards have different material types, and today we will first talk about common plywood boards. Following the pace of the past, let’s take a look at the video brought to us by the little expert. What kind of mystery is there?

Effect comparison:

For plywood, we found that different factors such as power, speed, focal length, and whether to blow air have different effects. Let’s analyze the logo cut out above as an example:

1.The Power Is Set To 45%—50%

Many people ask: Why do you need to set the minimum power and maximum power when cutting? In fact, the speed of laser cutting straight lines is faster than the speed of corners. In order to cut through the board, we will set the minimum power and maximum power. Furthermore, we need to know that in the case of cutting through the board, the higher the power setting, the better. If the power is too high, the cutting edge will be black, and the material There are serious problems such as serious reflection of the honeycomb panel on the back.

2.Speed Is Set To 35mm/s

We all know that the faster the speed, the higher the processing efficiency, but it is not recommended that you set the cutting speed only at the value that just cuts through the board. The unevenness and bending of the material itself may cause the laser to fail to cut through the board. Therefore, setting the cutting speed a bit slower will help the graphics to be completely cut through.

3.Blow

According to the previous experimental results, it is known that the cutting of plywood is the best with strong air blowing, so we might as well choose strong air blowing when cutting wood boards.

4.Focal Length 6mm

When it is necessary to cut through the wood, the focal length of the Leiyu laser is 6mm. Of course, make sure that the material is flat before cutting to avoid material waste caused by incorrect focus.

In conclusion:Let’s summarize the above analysis now. Combined with the effect of the previous issues on plywood (taking 3mm thickness as an example), we get the following conclusions:

- The power is set to 45%-50%

- Speed is set to 35mm/s

- Select air blow

- The focal length is set at 6mm

The last thing I need to remind everyone is that when we cut boards of different thicknesses, we need to appropriately change related parameters such as power and speed.