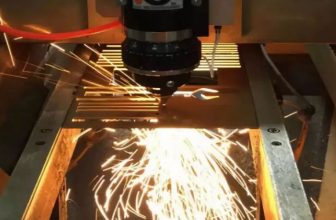

Laser cutting is so popular in large part because of its versatility. Laser cutters can cut a wide variety of materials, from paper, wood, cork, acrylic, foam to all kinds of metals. When using laser cutting, you should understand the characteristics of each material and pay more attention in the actual use process.

The Materials That Can Be Cut By Laser Cutting

1.Different Metals

Laser cutters can cut all types of metals from mild steel, stainless steel to non-ferrous metals. Highly reflective metals such as aluminum are more difficult to cut, and fiber lasers are a better choice in this case. Today, even metal can be cut up to 100mm thick, depending on the power of the laser.

2.Wood

All types of wood, including plywood and MDF, can be laser cut, but some oily woods present a risk of ignition and should be used with special care.

3.Paper And Cardboard

Paper is also suitable for laser cutting, and we have seen some intricate and beautiful wedding invitations that are likely made by laser cutting.

4.Plastic Products

Acrylic, PMMA and Lucite are all clear plastics. Laser cutting ensures a nice finish on the edges that looks like cream cut with a knife.

5.POM

Polyoxymethylene is a highly used plastic in engineering and can be used in gears, guide and sliding elements, medical devices, food packaging, etc. The ability to use lasers for complex cutting has contributed to the wider use of polyoxymethylene in many fields.

6.Glass

Laser cutting glass seems like an impossible task due to its fragile and reflective properties. However, laser cutters can cut glass.

Can’t Cut What?

It looks like a laser can cut just about anything, but no, most of the materials on the “can’t cut” list are various plastics.

1.PVC

Cutting PVC emits acid and toxic fumes, which are harmful to both the operator of the machine and the laser cutter itself, so PVC cutting should be left to mechanical methods.

2.Polycarbonate

Polycarbonate smaller than 1mm can be tried with a laser cutter, but it will cause discoloration of the material.

If the material is thick, there is no way to use laser cutting, not only is it inefficient, the material is severely discolored, and it may cause burns.

3.ABS, HDPE

Usually, the temperature of the laser beam is enough to vaporize the material, but materials like ABS, HDPE are not supported. They tend to melt more than vaporize, leaving a messy workbench and poor quality cuts.

4.Polystyrene And Polypropylene Foam

Both are prone to fire.

5.Glass Fiber

Fiberglass is a mixture of two materials – glass and epoxy. Cutting glass alone is notoriously difficult, and adding a smoke-causing resin to the mix is a nightmare.