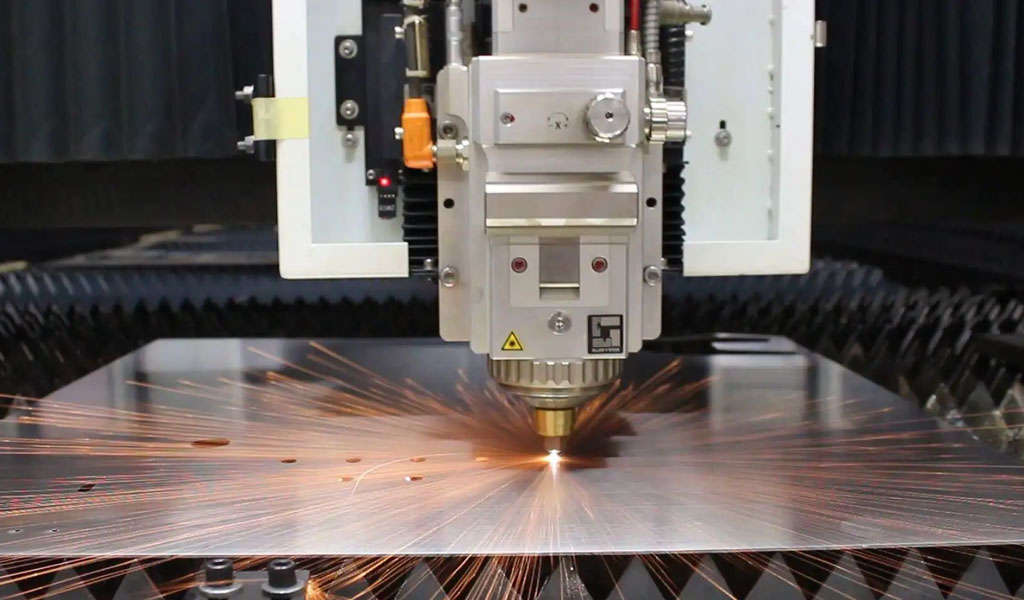

The advantage of a laser cutting machine is that it can quickly and accurately process aluminum foil into different shapes.

In current laser cutting systems, limitations in aerospace applications have been improved, and laser systems now largely reduce the size of the heat-affected zone (HAZ) and the corresponding microcracks. In the laser cutting process, technicians can already control the cutting parameters and use the calculator software to make precise repetitions. These technological advancements have led to a rethinking of the suitability of laser cutting for the production of fuselage structures. The fuselage structure is mainly made of 7000 series aluminum material.

Fatigue fractures usually occur where stress is concentrated, such as the edge of a part, at a geometry change, or at a joint. Airframe parts made of sheet metal have many different joints, and the vast majority of fatigue cracks occur at the joints. If the laser is not used to cut the small holes in the joint, the laser is mainly used for edge cutting of the part. For other effects, the most vulnerable joint location can be used to account for the micro-cracks caused by laser cutting and not the major damage location compared to the joint. In this way, we can conclude that if a part has the potential to break at the joint, the laser cutting technique will not further damage the fatigue properties of the part.

The laser cutting process can machine parts with consistency faster and it is more efficient than traditional machining. Laser technology promises to reduce processing time and production costs. For a long time, in the processing of 7000 series aluminum sheet, the advantages of the laser have not been realized due to the degradation of fatigue performance. Recent innovations in laser systems have re-evaluated the advantages of laser cutting and machining aluminum. Preliminary tests have shown the potential of laser technology in airframe machining. Future airframe systems as well as existing designs should not preclude possible use of lasers in such airframe systems based on past experience. We should keep an open mind and analyze various situations to determine whether laser technology can bring product benefits.