The specifications of acrylic sheets are generally relatively large, so tools are needed to cut them into appropriate sizes. So what are the methods for cutting acrylic sheets? Below, Pintejin will introduce you to the content of acrylic sheet cutting. Let’s take a look.

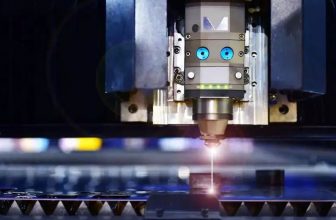

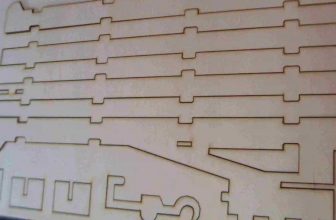

- Laser cutting: Laser cutting is a non-contact cutting method. The laser can cut various patterns, words, etc. The technology is to use the energy released by the laser beam to irradiate the acrylic surface to melt the acrylic sheet, and use the laser to melt the acrylic sheet. The cutting method can accurately cut complex shapes of materials, and the cut materials only need to be polished.

- Can be cut with hook knife: hand-cut acrylic board needs to use a hook knife, as long as the board is planned in advance, and then cut to half of the board with a hook knife, and then it can be broken by hand. If you want a neat edge, you can Do some sanding.

- Mechanical cutting is available: It is relatively simple to use mechanical cutting of acrylic sheets. Common machines include engraving machines, chainsaws and laser cutting machines. These tools can cut very good results, saving time and effort.

In Real Life, What Is The Acrylic Cutting Method When We Cut The Sheet?

1.What Is The Cutting Method Of Acrylic Sheet?

We can use equipment such as chainsaws or laser cutting machines to cut acrylic sheets. It needs to be polished after cutting. Simple polishing is to sand it by hand with sandpaper, and the surface needs to be polished to a smooth and flat surface. Burn it off with a flame, then slash it with a hook knife. Then gradually increase the strength. At this time, the electric drill cannot be used. If the material of the electric drill is relatively brittle, and the drill bit of the electric drill is relatively hot, the acrylic plate will be melted, and the operation cannot be continued.

If it is a very wide acrylic plate, you need to use a hook knife or a stainless steel saw to cut. At this time, the machine should be turned on and its speed should be adjusted to a low speed for cutting. Align the machine with the place to be cut. When cutting, keep the cuts in a line, so as to ensure that it cuts neat squares.

2.What Are The Characteristics Of Acrylic Board

- The permeability of acrylic sheet is particularly good, and its permeability can reach about 92%. Moreover, the color development ability of the acrylic sheet is particularly good. The acrylic sheet has very high weather resistance, and the hardness of the periphery is particularly hard. Its overall gloss and its high temperature resistance are relatively good.

- The metal of acrylic sheet has very good processing performance. During production, it can be divided into extrusion type and casting type. And it can be processed mechanically, and it can also make more exquisite shapes and patterns on it. Acrylic sheet can be laser engraved or laser cut to make excellent products.

Can Fiber Laser Cutting Machine Cut Acrylic?

This involves the wavelength of the laser (the wavelength of the fiber laser cutting machine is 1.06um, which is not easily absorbed by non-metals, so it cannot cut non-metallic materials);

- Why the processing category of metal laser cutting machine can only cut metal, but not non-metal such as cloth, leather, stone, etc. The reason is very simple, the wavelength range of fiber laser cutting machine is not within the absorption range of the above materials, or the absorption is not suitable , can not achieve the ideal cutting effect, at present, the advantages of non-metal cutting are not very obvious.

- Secondly, fiber laser cutting machine is not recommended for long-term cutting of rare metal materials such as aluminum and copper, because these materials are highly reflective materials (Note: high reflection has little to do with the smoothness of the cutting surface of the sheet, mainly because the wavelength of the laser is not in these Within the ideal absorption range of the material, the absorption effect is not good, most of the energy is reflected back, and it is easy to damage the protective lens in front of the laser head), the long-term use effect is not good, and the consumption of consumables will be increased;

- Finally, laser cutting machine, according to its power, the cutting thickness also changes. The greater the power, the greater the cutting thickness, the thinner the metal material, the faster the cutting speed. The special magnesium fiber laser cutting machine has obvious advantages for thin plate cutting. .