In general, when we work with sheet metal, we usually apply a certain force to the metal stock, such as sheet metal, thin-walled profiles and thin-walled tubes, so that it is plastically deformed or sheared to become a part with the desired shape and properties. Inevitably, this process involves the forming process of sheet metal working. So do you know what types of sheet metal working forming processes there are?

Types of sheet metal working forming processes.

1. Rolled edge

Sheet metal usually contains sharp edges with “burrs” after initial production. Edge rolling is a sheet metal forming process that involves deburring the sheet metal to produce a smooth edge.

2. Bending

Bending is a common sheet metal working and forming process, usually using a brake press or similar machine press to bend the sheet metal.

3、Punching

Punching is a sheet metal working forming process which involves the use of a punch and die to punch holes in the sheet metal. The sheet metal is placed between the punch and the die. Next, the punch is pressed downwards and through the sheet metal to form a hole.

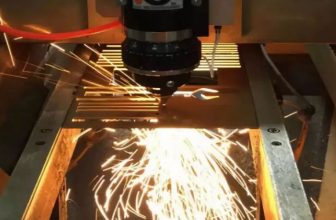

4、Laser cutting

In recent years, laser cutting has become an increasingly common forming process for sheet metal fabrication. With laser cutting, the sheet metal is exposed to a high energy laser which burns holes in the metal.

5、Hydroforming

A lesser known forming process for sheet metal fabrication is hydroforming. As with deep drawing, hydroforming involves stretching the blank over a die. The main difference between the two processes, hydroforming and deep drawing, then, is that deep drawing requires several reductions in the depth of the draw, whereas hydroforming can be done in just one step.

In summary, we can see that the types of sheet metal fabrication and forming processes include rolled edges, bending, punching, laser cutting, hydraulic forming and other methods.