During the whole process of welding, they must wear their work clothes reasonably before welding, and then wear rubber gloves and boots reasonably. In the whole process of welding, it is necessary to apply a respiratory mask, so as to avoid electric light damage to the skin , face and eyes.existLaser welding processingIn this case, the body should never touch the output ends of the two outputs of the welding machine, so that the electric shock accident can be avoided to a certain level.

When the gas cutting is used, it is not necessary to spray its flame into the person’s body and the rubber hose. Under normal circumstances, the welding parts cannot be touched immediately by hand.Laser welding processingIn actual operation, pay attention to the surrounding conditions under the circumstance of cleaning and piercing immediately, and reasonably control the flying direction of the welding slag to avoid hot slag scalding people or igniting objects. During the electric welding work, the natural ventilation should be excellent to prevent the harmful substances dissolved from the welding core from accumulating around the operator and affecting the health of the operator.

Do not use its human eyes to watch the electric light immediately during the whole process of the arc, and reasonably observe the surrounding conditions before starting the actual operation, so as to reasonably prevent the electric light from damaging itself and others. After the welding is completed, the switching power supply should be disconnected, and the residual fire that will exist on the spot should be removed before leaving.

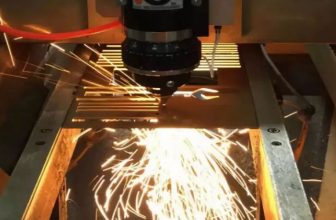

Laser welding processingUnder the circumstance, at a certain level, it is mainly based on heating or charging, which can promoteLaser welding processingA production and processing method for fusion of welded parts in the actual operation, it can be reasonably based on the difference in the whole process of electric welding.